Wrench size for coaxial cable plays a crucial role in ensuring proper installation and maintenance of these essential components. Understanding the correct wrench size and usage techniques is paramount to avoid damage and ensure optimal performance.

This comprehensive guide delves into the intricacies of wrench size compatibility, proper wrench usage, and alternative tools for coaxial cable connections. We’ll also explore the key specifications to consider when selecting a wrench and provide an overview of different coaxial cable types and their corresponding wrench size requirements.

Wrench Size Compatibility: Wrench Size For Coaxial Cable

When working with coaxial cables, it is crucial to use the appropriate wrench size to ensure a secure connection and prevent damage to the cable or connectors. Different types of coaxial cables have specific wrench size requirements, and using the wrong size can lead to loose connections, signal loss, or even damage to the cable.

Wrench Size Table

The following table provides a comprehensive list of common coaxial cable types and their corresponding wrench sizes:

| Coaxial Cable Type | Wrench Size |

|---|---|

| RG-58 | 7/16″ |

| RG-59 | 7/16″ |

| RG-6 | 9/16″ |

| RG-11 | 11/16″ |

| RG-213 | 1-1/8″ |

| RG-214 | 1-1/8″ |

Proper Wrench Usage

Using a wrench correctly is crucial for maintaining the integrity of coaxial cables. Improper techniques can damage the cable, affecting its performance and lifespan.

Applying the Correct Torque, Wrench size for coaxial cable

When tightening or loosening the connectors on a coaxial cable, it’s essential to apply the appropriate torque. Over-tightening can crush the connector or damage the cable’s core, while under-tightening can lead to a loose connection and signal loss.

The recommended torque for coaxial cables varies depending on the type of connector and cable. Consult the manufacturer’s specifications or use a torque wrench to ensure you apply the correct amount of force.

Wrench Alternatives

In certain situations, a traditional wrench may not be readily available or suitable for tightening or loosening coaxial cable connections. Fortunately, there are several alternative tools that can be employed to achieve the same result.

The following table compares the advantages and disadvantages of different wrench alternatives:

| Tool | Advantages | Disadvantages |

|---|---|---|

| Needle-nose pliers | – Compact and easy to handle

|

– Less torque than a wrench

|

| Channel-lock pliers | – Provide a secure grip

|

– Can be bulky and difficult to use in tight spaces

|

| Spanner wrench | – Designed specifically for coaxial cable connections

|

– More expensive than other alternatives

For those tackling coaxial cable projects, selecting the appropriate wrench size is crucial. Whether you’re navigating the competitive job market or embarking on a home improvement endeavor, knowing the right tools is essential. Just as the jp morgan superday offer rate can impact career prospects, the correct wrench size ensures a secure and efficient coaxial cable installation. Understanding the nuances of both domains empowers you to tackle any challenge with precision.

|

Wrench Specifications

Selecting the appropriate wrench for coaxial cables is crucial to ensure proper installation and performance. Key specifications to consider include wrench material, size, and design.

The choice of wrench material influences its durability, strength, and resistance to wear and tear. Common materials include hardened steel, aluminum, and plastic. Hardened steel wrenches offer exceptional durability and longevity, while aluminum wrenches are lightweight and resistant to corrosion.

Plastic wrenches are cost-effective but may not be suitable for heavy-duty applications.

Wrench Size

The size of the wrench is determined by the diameter of the coaxial cable’s connector. Wrenches come in various sizes to accommodate different cable diameters. Using a wrench that is too small or too large can damage the connector or make it difficult to achieve a secure connection.

Wrench Design

Wrench design plays a significant role in ease of use and efficiency. Wrenches can feature different handle designs, such as T-handles, L-handles, or straight handles. T-handles provide increased leverage and torque, while L-handles offer better accessibility in tight spaces. Straight handles are commonly used for quick and simple adjustments.

Coaxial Cable Types

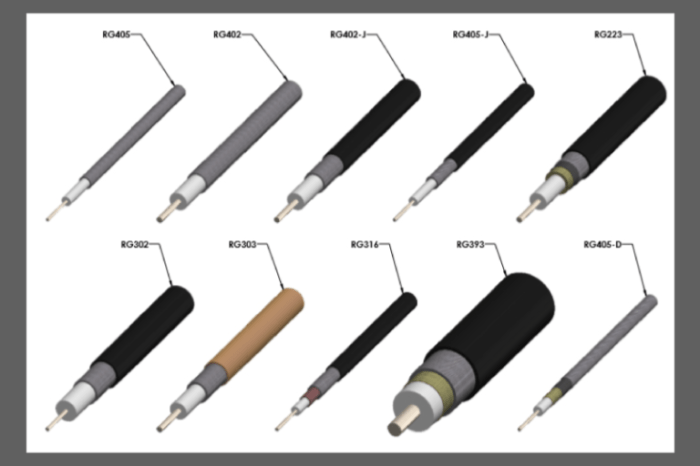

Coaxial cables come in various types, each designed for specific applications. Understanding the different types of coaxial cables is crucial for selecting the appropriate wrench size.

Cable Variations and Wrench Size Requirements

Coaxial cables vary in terms of their outer diameter, shielding, and impedance. These variations influence the wrench size required to connect or disconnect the cable. Common coaxial cable types include:

- RG-58:A thin and flexible cable with a small outer diameter, typically used in low-power applications and requires a small wrench.

- RG-6:A thicker and more durable cable, commonly used in home networking and requires a medium-sized wrench.

- RG-11:A thick and high-performance cable, used in long-distance data transmission and requires a large wrench.

It’s important to consult the cable manufacturer’s specifications to determine the exact wrench size required for a specific coaxial cable type. Using an incorrect wrench size can damage the cable or connectors.

Wrench Sizes for Specialized Applications

Specialized coaxial cable applications, such as those in broadcasting, telecommunications, and military, require specific wrenches to ensure optimal performance and durability. These wrenches are designed with unique features and benefits to meet the demands of these specialized applications.

Unique Features of Specialized Wrenches

-

-*Precise Jaw Design

Specialized wrenches have precision-machined jaws that conform precisely to the hexagonal shape of the coaxial cable connector, preventing slippage and damage.

-*High Torque Capacity

These wrenches are engineered to handle high torque requirements, enabling the secure tightening and loosening of coaxial cable connectors.

-*Corrosion Resistance

Specialized wrenches are often made from corrosion-resistant materials, such as stainless steel, to withstand harsh environments and ensure longevity.

-*Ergonomic Handles

They often feature ergonomic handles for increased comfort and ease of use, especially during prolonged use.

-*Specialized Tips

Some specialized wrenches have tips designed for specific connector types, such as F-connectors or BNC connectors, ensuring a perfect fit and preventing damage.

Answers to Common Questions

What is the most common wrench size for coaxial cables?

The most common wrench size for coaxial cables is 7/16 inch.

Can I use pliers to tighten coaxial cable connections?

While pliers can be used in emergencies, it’s not recommended as they can damage the cable or connector.

How do I know if I’m using the correct wrench size?

The correct wrench size should fit snugly on the connector without any play or excessive force required.